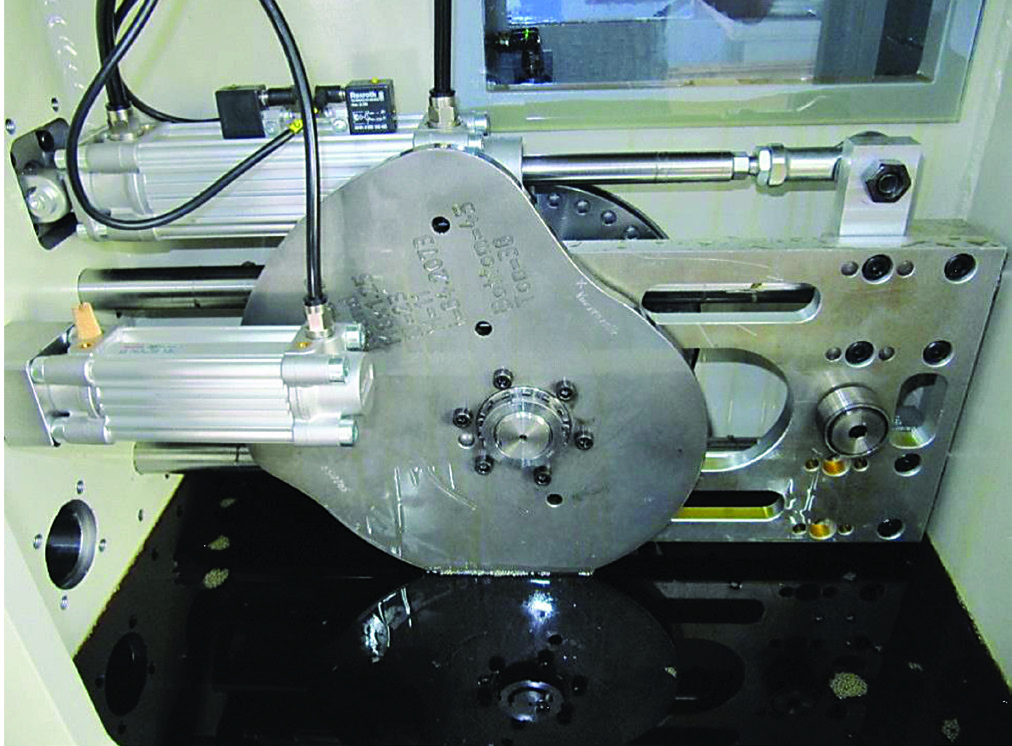

The primary gain is the ability to run at much higher speeds and still maintain the best thread quality. The tap life can still be as good as in machines that run at half the speed.

Streicher Maschinenbau GmbH has been manufacturing tapping machines for almost 80 years. Nearly 2000 machines have been produced by Streicher and are distributed in more than 70 countries.

Over the years, there has been a variety of different tapping machines, both bent shank (over tapping) and reversing style. Today, the primary nut tapping machines we are making is a series of two

Eliminating the speed and feed variable in tapping machines has proven advantages. The primary gain is the ability to run at much higher speeds and still maintain the best thread quality. The tap life can still be as good as in machines that run at half the speed.